-

Surface Grinder

- "EQUIPTOP" Double Column Grinder

- "EQUIPTOP" Manual

- "EQUIPTOP" Semi-automatic

- "EQUIPTOP" Automatic (Mechanical Type)

- "EQUIPTOP" Automatic (Digital Type)

- Cylindrical Grinder

- Centerless Grinder

- CNC Vertical Grinder

- "POWERFUL" High Precision Surface Grinder

- "WEIHAI HUADONG" Surface Grinder

- "HOWIN" Surface Grinder

- Machining Center

- CNC Engraving and milling machine

- CNC EDM

- CNC Wire Cutting Machine

- Milling Machine

- Lathe

- Drilling machines

- Press

- Hydraulic Press

- Sheet Metal Machine

- Metal Band Saw

Head Office:

HO WIN MACHINERY CO.

Address: Room. 1201, 12/F., Man Shing Industrial Building, 307-311 Castle Peak Road, Kwai Chung, N.T. HK.

Tel:852-26685075

Fax:852-39046475

E-mail: info@howin.hk

Web Site: www.howin.hk

China Showroom:

HO WIN MACHINERY CO.

Address: No.7, Maiyuanlu 4 Xiang, Xin'An Community, Chang'An Town, Dong Guan City, Guangdong, China.

Tel:86-769-85328685 85314541

Fax:86-769-85328535

E-mail: howin@163.com

Web Site: www.howin.hk

| Product name | Centerless Grinder |

| Performance of work table | ---- |

| Longitudinal movement table (No paragraph table speed) |

---- |

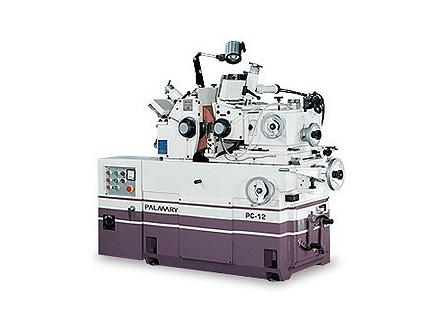

PC-12

Features:

- Rigid Machine Structure

- .The machine structure is manufactured from high quality Meeharite cast iron, heat treated and stress relieved before machining.

- .Sideways are high frequency hardened and precision ground. Maximum material stability for deformation-free and outstanding wear resistance.

- Precision Spindles

- .The grinding wheel spindle and the regulating wheel spindle are precision machined from Nickel Chromolybedenum alloy steel (SNCM-220). Also, they are subject to various treatments such as: normalized, tempered and carburized hardening. Then, the spindles are thru sub-zero treated – under zero degrees, precision ground and precision machined.

- .The inside of spindle is tempered to hardness HRC 25°~30°, while surface hardness reaches over HRC 62. The precision ground spindle is excellent for heavy-duty machining and features powerful torque, long service life, deformation-free and maximum wear resistance.

- Slide Table

- .Upper slide swiveling is easy and accurate to adjust for making the machine suitable for infeeding grinding. Also, it allows grinding for a varied diameter fo workpieces. The Upper slide with +5°~-5° swiveling allows taper grinding by using infeed grinding mode.

- .With thrufeed grinding, the Upper slide provides a surface contact adjustment between the workpiece and grinding wheel. Swiveling adjustment range is +5°~-3°.

- .Dovetailed slideway on the upper slide features smooth and accurate feeding and is lubricated by a centralized lubricator.

- .The bottom slide moves on “Λ” shaped and double-wedged ways.

- The slideways are hardened and precision ground. They feature smooth movement and properly protected to prevent dust from entering. Micrometric feed adjustment unit is 0.001 mm to meet high accuracy requirements for all workpieces.

- Feed Screw

- .The feed screw is manufactured from Nickel Chromolybedenum alloy steel (SNCM-4). It is also normalized, high frequency hardened treated and precision ground.

- .Specially-designed adjustable nut features easy adjustment, high feeding accuracy, smooth motion and excellent wear resistance.

- Automatic Unloading Equipment for Thrufeed Grinding (optional)

- .Designed for automatic unloading for round tube and bar stock, this equipment can avoid workpiece surface scratching. It is also suitable for online operation while performing two to three grinding processes. The conveyor is easy to adjust. Equipped with a parts tray for convenient parts collection after grinding.

- Lubrication System

- .The automatic lubricator provides lubrication to the grinding wheel spindle.

- .All slideways are lubricated by a centralized lubrication system, ensuring proper lubrication and feeding accuracy.

- Automatic Loading Equipment for Thrufeed Grinding(Optional)

- .Suitable for automatic loading operation for round tube and bar stock.

- .Equipped with a storage tray for automatic workpiece infeed.

- .It eliminates manual workpiece infeed while enormously increasing total efficiency.

- Pressure Switch

- .When starting the grinding wheel and regulating wheel spindle, this pressure switch all ows starting only when oil enters into bearings thereby providing safety protection for the spindle bearings.

- Hydraulic Cooling Device

- .The lubrication system for bearings on grinding wheel spindle, regulating wheel spindle and hydraulic system are driven by the same hydraulic pump. A cooling fan is equipped for effectively reducing oil temperature.

- Dresser for Grinding Wheel and Regulating Wheel

- .Dresser structure is manufactured from alloy cast iron and is heat treated for wear resistance.

- .Hydraulically operated dressing motion.

- .Variable dressing speed.

- .Dresser stand for regulating wheel can be adjusted to suit workpiece requirements, assuring high cylindrical accuracy.

| SPECIFICATIONS | PC-12 | PC-14 | PC-16 |

| Grinding Wheel | |||

| Standard grinding range (Dia.) | Ø1~Ø40 mm | Ø1~Ø40 mm | Ø1~Ø50 mm |

| Capacity increases with special arrangement | Ø30~Ø60 mm | Ø30~Ø60 mm | Ø40~Ø100 mm |

| Grinding wheel size (O.D. x width x I.D.) | Ø305 x 150 x Ø120 | Ø355 x 150 x Ø180 | Ø405 x 205 x Ø203.2 |

| Grinding wheel speed | 1900 R.P.M. | 1637 R.P.M. | 1600 R.P.M. |

| Grinding wheel motor | 7-1/2 HP x 4P | 7-1/2 HP x 4P | 7-1/2 HP x 4P |

| Regulating Wheel | |||

| Regulating wheel size (O.D. x width x I.D.) | Ø205 x 150 x Ø90 | Ø205 x 150 x Ø90 | Ø255 x 205 x Ø111.2 |

| Regulating wheel speed | 20~337 R.P.M. (10 Steps) | 20~337 R.P.M. (10 Steps) | 13~308 R.P.M. (10 Steps) |

| Regulating wheel motor | 1HP x 6P | 1HP x 6P | 2HP x 6P |

| Regulating wheel tilt angle | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° |

| Regulating wheel swivel angle | ±5° | ±5° | ±5° |

| Handwheel Graduation | |||

| Upper slide feed graduation | 4 mm/rev. 0.025 mm/graduation | 4 mm/rev. 0.025 mm/graduation | 3.5 mm/rev. 0.05 mm/graduation |

| Upper slide micro-feed graduation | 0.1 mm/rev. 0.001 mm/graduation | 0.1 mm/rev. 0.001 mm/graduation | 0.1 mm/rev. 0.001 mm/graduation |

| Lower slide feed graduation | 7 mm/rev. 0.05 mm/graduation | 7 mm/rev. 0.05 mm/graduation | 9 mm/rev. 0.05 mm/graduation |

| Lower slide micro-feed graduation | 0.2 mm/rev. 0.001 mm/graduation | 0.2 mm/rev. 0.001 mm/graduation | 0.2 mm/rev. 0.001 mm/graduation |

| Trimming device graduation | 1.25 mm/rev. 0.01 mm/graduation | 1.25 mm/rev. 0.01 mm/graduation | 2 mm/rev. 0.01 mm/graduation |

| Drive Motors | |||

| Hydraulic pump motor | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P |

| Coolant pump motor | 1/8 HP x 2P | 1/8 HP x 2P | 1/4 HP x 2P |

| Machine Dimensions | 1750 x 1050 x 1400 mm | 1750 x 1050 x 1400 mm | 2100 x 1700 x 1500 mm |

| Net weight | 1650 kgs | 1750 kgs | 2400 kgs |

| Gross weight | 1900 kgs | 2000 kgs | 2700 kgs |

| Packing dimensions | 1880 x 1550 1820 mm | 1880 x 1550 1820 mm | 2280 x 2000 x 1850 mm |

Specifications:

| PC-18 | PC-1810 | PC-20 | |

| Grinding Wheel | |||

| Standard grinding range (Dia.) | Ø1~Ø80 mm | Ø1~Ø80 mm | Ø1~Ø80 mm |

| Capacity increases with special arrangement | Ø40~Ø150 mm | Ø40~Ø150 mm | Ø40~Ø150 mm |

| Grinding wheel size (O.D. x width x I.D.) | Ø455 x 205 x Ø228.6 | Ø455 x 255 x Ø228.6 | Ø510 x 205 x Ø304.8 |

| Grinding wheel speed | 1500 R.P.M. | 1500 R.P.M. | 1200 R.P.M. |

| Grinding wheel motor | 15 HP x 4P | 15 HP x 4P | 20 HP x 4P |

| Regulating Wheel | |||

| Regulating Wheel size (O.D. x width x I.D.) | Ø255 x 205 x Ø111.2 | Ø255 x 255 x Ø111.2 | Ø305 x 205 x Ø127 |

| Regulating Wheel speed | 13~308 R.P.M. (Variable) | 13~308 R.P.M. (Variable) | 13~308 R.P.M. (Variable) |

| Regulating Wheel motor | 2 HP x 6P | 2 HP x 6P | 3 HP x 6P |

| Regulating Wheel tilt angle | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° |

| Regulating Wheel swivel angle | ±5° | ±5° | ±5° |

| Handwheel Graduation | |||

| Upper slide feed graduation | 3.5 mm/rev. 0.05 mm/graduation | 3.5 mm/rev. 0.05 mm/graduation | 3.5 mm/rev. 0.05 mm/graduation |

| Upper slide micro-feed graduation | 0.1 mm/rev. 0.001 mm/graduation | 0.1 mm/rev. 0.001 mm/graduation | 0.1 mm/rev. 0.001 mm/graduation |

| Lower slide feed graduation | 9 mm/rev. 0.05 mm/graduation | 9 mm/rev. 0.05 mm/graduation | 9 mm/rev. 0.05 mm/graduation |

| Lower slide micro-feed graduation | 0.2 mm/rev. 0.001 mm/graduation | 0.2 mm/rev. 0.001 mm/graduation | 0.2 mm/rev. 0.001 mm/graduation |

| Trimming device graduation | 2 mm/rev. 0.01 mm/graduation | 2 mm/rev. 0.01 mm/graduation | 2 mm/rev. 0.01 mm/graduation |

| Drive Motors | |||

| Hydraulic pump motor | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P |

| Coolant pump motor | 1/4 HP x 2P | 1/4 HP x 2P | 1/4 HP x 2P |

| Machine Dimensions | 2200 x 1840 x 1530 mm | 2200 x 1840 x 1530 mm | 2200 x 1900 x 1530 mm |

| Net weight | 2900 kgs | 3000 kgs | 3700 kgs |

| Gross weight | 3200 kgs | 3300 kgs | 4000 kgs |

| Packing dimensions | 2280 x 1940 x 1850 mm | 2280 x 1940 x 1850 mm | 2280 x 2100 x 1900 mm |

Standard Accessories:

1. Regulating wheel and flange (1 set) (mounted on machine)

2. Grinding wheel and flange (1 set) (mounted on machine)

3. Infeed work rest and carbide blade (1 set)

4. Thrufeed work rest and carbide blade (1 set)

5. Standard electric equipment (1 set) ( mounted on machine)

6. Oil tank (1 set) (ind. Oil cooling fan)

7. Standard coolant system (1 set)

8. Diamond tools (2 pcs) (mounted on machine)

9. Work lamp (1 set) (mounted on machine)

10. Tool box and Tools (1 set)

2. Grinding wheel and flange (1 set) (mounted on machine)

3. Infeed work rest and carbide blade (1 set)

4. Thrufeed work rest and carbide blade (1 set)

5. Standard electric equipment (1 set) ( mounted on machine)

6. Oil tank (1 set) (ind. Oil cooling fan)

7. Standard coolant system (1 set)

8. Diamond tools (2 pcs) (mounted on machine)

9. Work lamp (1 set) (mounted on machine)

10. Tool box and Tools (1 set)

Optional Accessories:

1. Wheel balancing stand and arbor

2. Automatic infeed attachment

3. Manual feeder for infeed grinding (up and down)

4. Hydraulic work ejector (infeed grinding)

5. Automatic loading attachment (thrufeed grinding) (Ø5-20 mm, L100-600 mm)

6. Automatic feeder for thrufeed grinding (hopper type) (Ø2-8 mm, L50-180 mm)

7. Automatic unloading attachment (thrufeed grinding)

8. V Type Supporter for long bar grinding

9. Profile grinding attachment

10. Magnetic coolant separator

11. Magnetic with paper filter

12. Hydrocyclone coolant separator

13. Auto. Loading and unloading attachment (infeed grinding)

14. Vibratory feeder (thrufeed grinding)

15. Large work rest (thrufeed grinding) L:250 – 500 mm

2. Automatic infeed attachment

3. Manual feeder for infeed grinding (up and down)

4. Hydraulic work ejector (infeed grinding)

5. Automatic loading attachment (thrufeed grinding) (Ø5-20 mm, L100-600 mm)

6. Automatic feeder for thrufeed grinding (hopper type) (Ø2-8 mm, L50-180 mm)

7. Automatic unloading attachment (thrufeed grinding)

8. V Type Supporter for long bar grinding

9. Profile grinding attachment

10. Magnetic coolant separator

11. Magnetic with paper filter

12. Hydrocyclone coolant separator

13. Auto. Loading and unloading attachment (infeed grinding)

14. Vibratory feeder (thrufeed grinding)

15. Large work rest (thrufeed grinding) L:250 – 500 mm

PC-18/1810/20

● Regulating wheel is driven by servomotor

● Low speeds; hing torque output.

● Easy to operate and adjust.

● Regulating wheel is driven by servomotor.

● Low speed; high torque output.

● Easy to operate and adjust.

Features:

- Rigid Machine Structure

- .The machine structure is manufactured from high quality Meeharite cast iron, heat treated and stress relieved before machining.

- .Sideways are high frequency hardened and precision ground. Maximum material stability for deformation-free and outstanding wear resistance.

- Precision Spindles

- .The grinding wheel spindle and the regulating wheel spindle are precision machined from Nickel Chromolybedenum alloy steel (SNCM-220). Also, they are subject to various treatments such as: normalized, tempered and carburized hardening. Then, the spindles are thru sub-zero treated – under zero degrees, precision ground and precision machined.

- .The inside of spindle is tempered to hardness HRC 25°~30°, while surface hardness reaches over HRC 62. The precision ground spindle is excellent for heavy-duty machining and features powerful torque, long service life, deformation-free and maximum wear resistance.

- Slide Table

- .Upper slide swiveling is easy and accurate to adjust for making the machine suitable for infeeding grinding. Also, it allows grinding for a varied diameter fo workpieces. The Upper slide with +5°~-5° swiveling allows taper grinding by using infeed grinding mode.

- .With thrufeed grinding, the Upper slide provides a surface contact adjustment between the workpiece and grinding wheel. Swiveling adjustment range is +5°~-3°.

- .Dovetailed slideway on the upper slide features smooth and accurate feeding and is lubricated by a centralized lubricator.

- .The bottom slide moves on “Λ” shaped and double-wedged ways.

- The slideways are hardened and precision ground. They feature smooth movement and properly protected to prevent dust from entering. Micrometric feed adjustment unit is 0.001 mm to meet high accuracy requirements for all workpieces.

- Feed Screw

- .The feed screw is manufactured from Nickel Chromolybedenum alloy steel (SNCM-4). It is also normalized, high frequency hardened treated and precision ground.

- .Specially-designed adjustable nut features easy adjustment, high feeding accuracy, smooth motion and excellent wear resistance.

- Automatic Unloading Equipment for Thrufeed Grinding (optional)

- .Designed for automatic unloading for round tube and bar stock, this equipment can avoid workpiece surface scratching. It is also suitable for online operation while performing two to three grinding processes. The conveyor is easy to adjust. Equipped with a parts tray for convenient parts collection after grinding.

- Lubrication System

- .The automatic lubricator provides lubrication to the grinding wheel spindle.

- .All slideways are lubricated by a centralized lubrication system, ensuring proper lubrication and feeding accuracy.

- Automatic Loading Equipment for Thrufeed Grinding(Optional)

- .Suitable for automatic loading operation for round tube and bar stock.

- .Equipped with a storage tray for automatic workpiece infeed.

- .It eliminates manual workpiece infeed while enormously increasing total efficiency.

- Pressure Switch

- .When starting the grinding wheel and regulating wheel spindle, this pressure switch all ows starting only when oil enters into bearings thereby providing safety protection for the spindle bearings.

- Hydraulic Cooling Device

- .The lubrication system for bearings on grinding wheel spindle, regulating wheel spindle and hydraulic system are driven by the same hydraulic pump. A cooling fan is equipped for effectively reducing oil temperature.

- Dresser for Grinding Wheel and Regulating Wheel

- .Dresser structure is manufactured from alloy cast iron and is heat treated for wear resistance.

- .Hydraulically operated dressing motion.

- .Variable dressing speed.

- .Dresser stand for regulating wheel can be adjusted to suit workpiece requirements, assuring high cylindrical accuracy.

Specifications:

| SPECIFICATIONS | PC-12 | PC-12S | PC-12S-NC | PC-14 | PC-14S | PC-14S-NC | PC-16 | PC-16S | PC-16S-NC |

| Grinding Wheel | |||||||||

| Standard grinding range (Dia.) | Ø1~Ø40 mm | Ø1~Ø40 mm | Ø1~Ø40 mm | Ø1~Ø40 mm | Ø1~Ø40 mm | Ø1~Ø40 mm | Ø1~Ø50 mm | Ø1~Ø50 mm | Ø1~Ø50 mm |

| Capacity increases with special arrangement | Ø30~Ø60 mm | Ø30~Ø60 mm | Ø30~Ø60 mm | Ø30~Ø60 mm | Ø30~Ø60 mm | Ø30~Ø60 mm | Ø40~Ø100 mm | Ø40~Ø100 mm | Ø40~Ø100 mm |

| Grinding wheel size (O.D. x width x I.D.) | Ø305 x 150 x Ø120 | Ø305 x 150 x Ø120 | Ø305 x 150 x Ø120 | Ø355 x 150 x Ø180 | Ø355 x 150 x Ø180 | Ø355 x 150 x Ø180 | Ø405 x 205 x Ø203.2 | Ø405 x 205 x Ø203.2 | Ø405 x 205 x Ø203.2 |

| Grinding wheel speed | 1900 R.P.M. | 1900 R.P.M. | 1900 R.P.M. | 1637 R.P.M. | 1637 R.P.M. | 1637 R.P.M. | 1600 R.P.M. | 1600 R.P.M. | 1600 R.P.M. |

| Grinding wheel motor | 7-1/2 HP x 4P | 7-1/2 HP x 4P | 7-1/2 HP x 4P | 7-1/2 HP x 4P | 7-1/2 HP x 4P | 7-1/2 HP x 4P | 10 HP x 4P | 10 HP x 4P | 10 HP x 4P |

| Regulating Wheel | |||||||||

| Regulating wheel size (O.D. x width x I.D.) | Ø205 x 150 x Ø90 | Ø205 x 150 x Ø90 | Ø205 x 150 x Ø90 | Ø205 x 150 x Ø90 | Ø205 x 150 x Ø90 | Ø205 x 150 x Ø90 | Ø255 x 205 x Ø111.2 | Ø255 x 205 x Ø111.2 | Ø255 x 205 x Ø111.2 |

| Regulating wheel speed | 20 ~ 337 R.P.M. (10 Steps) | 10 ~ 300 R.P.M. (Variable) | 10 ~ 300 R.P.M. (Variable) | 20 ~ 337 R.P.M. (10 Steps) | 10 ~ 300 R.P.M. (Variable) | 10 ~ 300 R.P.M. (Variable) | 13 ~ 308 R.P.M. (10 Steps) | 10~300 R.P.M. (Variable) | 10~300 R.P.M. (Variable) |

| Regulating wheel motor | 1HP x 6P | 1.5 KW servo motor | 1.5 KW servo motor | 1HP x 6P | 1.5 KW servo motor | 1.5 KW servo motor | 2HP x 6P | 2.0 KW servo motor | 2.0 KW servo motor |

| Regulating wheel tilt angle | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° |

| Regulating wheel swivel angle | ±5° | ±5° | ±5° | ±5° | ±5° | ±5° | ±5° | ±5° | ±5° |

| Handwheel Graduation | |||||||||

| Upper slide feed graduation | 4 mm/rev. 0.025 mm/graduation | 4 mm/rev. 0.025 mm/graduation | 4 mm/rev. 0.025 mm/graduation | 4 mm/rev. 0.025 mm/graduation | 4 mm/rev. 0.025 mm/graduation | 4 mm/rev. 0.025 mm/graduation | 3.5 mm/rev. 0.05 mm/graduation | 3.5 mm/rev. 0.05 mm/graduation | 3.5 mm/rev. 0.05 mm/graduation |

| Upper slide micro-feed graduation | 0.1 mm/rev. 0.001 mm/graduation | 0.1 mm/rev. 0.001 mm/graduation | 0.1 mm/rev. 0.001 mm/graduation | 0.1 mm/rev. 0.001 mm/graduation | 0.1 mm/rev. 0.001 mm/graduation | 0.1 mm/rev. 0.001 mm/graduation | 0.1 mm/rev. 0.001 mm/graduation | 0.1 mm/rev. 0.001 mm/graduation | 0.1 mm/rev. 0.001 mm/graduation |

| Lower slide feed graduation | 7 mm/rev. 0.05 mm/graduation | 7 mm/rev. 0.05 mm/graduation | 7 mm/rev. 0.05 mm/graduation | 7 mm/rev. 0.05 mm/graduation | 7 mm/rev. 0.05 mm/graduation | 7 mm/rev. 0.05 mm/graduation | 9 mm/rev. 0.05 mm/graduation | 9 mm/rev. 0.05 mm/graduation | 9 mm/rev. 0.05 mm/graduation |

| Lower slide micro-feed graduation | 0.2 mm/rev. 0.001 mm/graduation | 0.2 mm/rev. 0.001 mm/graduation | 0.2 mm/rev. 0.001 mm/graduation | 0.2 mm/rev. 0.001 mm/graduation | 0.2 mm/rev. 0.001 mm/graduation | 0.2 mm/rev. 0.001 mm/graduation | 0.2 mm/rev. 0.001 mm/graduation | ||

| Trimming device graduation | 1.25 mm/rev. 0.01 mm/graduation | 1.25 mm/rev. 0.01 mm/graduation | 1.25 mm/rev. 0.01 mm/graduation | 1.25 mm/rev. 0.01 mm/graduation | 1.25 mm/rev. 0.01 mm/graduation | 1.25 mm/rev. 0.01 mm/graduation | 2 mm/rev. 0.01 mm/graduation | 2 mm/rev. 0.01 mm/graduation | 2 mm/rev. 0.01 mm/graduation |

| Drive Motors | |||||||||

| Hydraulic pump motor | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P |

| Coolant pump motor | 1/8 HP x 2P | 1/8 HP x 2P | 1/8 HP x 2P | 1/8 HP x 2P | 1/8 HP x 2P | 1/8 HP x 2P | 1/4 HP x 2P | 1/4 HP x 2P | 1/4 HP x 2P |

| Machine Dimensions | |||||||||

| Machine Dimensions | 1750 x 1050 x 1400 mm | 1750 x 1050 x 1400 mm | 1750 x 1050 x 1400 mm | 1750 x 1050 x 1400 mm | 1750 x 1050 x 1400 mm | 1750 x 1050 x 1400 mm | 2100 x 1700 x 1500 mm | 2100 x 1700 x 1500 mm | 2100 x 1700 x 1500 mm |

| Net weight | 1650 kgs | 1650 kgs | 1700 kgs | 1750 kgs | 1750 kgs | 1800 kgs | 2400 kgs | 2400 kgs | 2450 kgs |

| Gross weight | 1900 kgs | 1900 kgs | 1950 kgs | 2000kgs | 2000kgs | 2050 kgs | 2700 kgs | 2700 kgs | 2750 kgs |

| SPECIFICATIONS | PC-18 | PC-1810 | PC-20 |

| Grinding Wheel | |||

| Standard grinding range (Dia.) | Ø1~Ø80 mm | Ø1~Ø80 mm | Ø1~Ø80 mm |

| Capacity increases with special arrangement | Ø40~Ø150 mm | Ø40~Ø150 mm | Ø40~Ø150 mm |

| Grinding wheel size (O.D. x width x I.D.) | Ø455 x 205 x Ø228.6 | Ø455 x 255 x Ø228.6 | Ø510 x 205 x Ø304.8 |

| Grinding wheel speed | 1500 R.P.M. | 1500 R.P.M. | 1200 R.P.M. |

| Grinding wheel motor | 15 HP x 4P | 15 HP x 4P | 20 HP x 4P |

| Regulating Wheel | |||

| Regulating Wheel size (O.D. x width x I.D.) | Ø255 x 205 x Ø111.2 | Ø255 x 255 x Ø111.2 | Ø305 x 205 x Ø127 |

| Regulating Wheel speed | 13~308 R.P.M. (Variable) | 13~308 R.P.M. (Variable) | 13~308 R.P.M. (Variable) |

| Regulating Wheel motor | 2 HP x 6P | 2 HP x 6P | 3 HP x 6P |

| Regulating Wheel tilt angle | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° |

| Regulating Wheel swivel angle | ±5° | ±5° | ±5° |

| Handwheel Graduation | |||

| Upper slide feed graduation | 3.5 mm/rev. 0.05 mm/graduation | 3.5 mm/rev. 0.05 mm/graduation | 3.5 mm/rev. 0.05 mm/graduation |

| Upper slide micro-feed graduation | 0.1 mm/rev. 0.001 mm/graduation | 0.1 mm/rev. 0.001 mm/graduation | 0.1 mm/rev. 0.001 mm/graduation |

| Lower slide feed graduation | 9 mm/rev. 0.05 mm/graduation | 9 mm/rev. 0.05 mm/graduation | 9 mm/rev. 0.05 mm/graduation |

| Lower slide micro-feed graduation | 0.2 mm/rev. 0.001 mm/graduation | 0.2 mm/rev. 0.001 mm/graduation | 0.2 mm/rev. 0.001 mm/graduation |

| Trimming device graduation | 2 mm/rev. 0.01 mm/graduation | 2 mm/rev. 0.01 mm/graduation | 2 mm/rev. 0.01 mm/graduation |

| Drive Motors | |||

| Hydraulic pump motor | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P |

| Coolant pump motor | 1/4 HP x 2P | 1/4 HP x 2P | 1/4 HP x 2P |

| Machine Dimensions | 2200 x 1840 x 1530 mm | 2200 x 1840 x 1530 mm | 2200 x 1900 x 1530 mm |

| Net weight | 2900 kgs | 3000 kgs | 3700 kgs |

| Gross weight | 3200 kgs | 3300 kgs | 4000 kgs |

| Packing dimensions | 2280 x 1940 x 1850 mm | 2280 x 1940 x 1850 mm | 2280 x 2100 x 1900 mm |

Standard Accessories:

1. Regulating wheel and flange (1 set) (mounted on machine)

2. Grinding wheel and flange (1 set) (mounted on machine)

3. Infeed work rest and carbide blade (1 set)

4. Thrufeed work rest and carbide blade (1 set)

5. Standard electric equipment (1 set) ( mounted on machine)

6. Oil tank (1 set) (ind. Oil cooling fan)

7. Standard coolant system (1 set)

8. Diamond tools (2 pcs) (mounted on machine)

9. Work lamp (1 set) (mounted on machine)

10. Tool box and Tools (1 set)

2. Grinding wheel and flange (1 set) (mounted on machine)

3. Infeed work rest and carbide blade (1 set)

4. Thrufeed work rest and carbide blade (1 set)

5. Standard electric equipment (1 set) ( mounted on machine)

6. Oil tank (1 set) (ind. Oil cooling fan)

7. Standard coolant system (1 set)

8. Diamond tools (2 pcs) (mounted on machine)

9. Work lamp (1 set) (mounted on machine)

10. Tool box and Tools (1 set)

Optional Accessories:

1. Wheel balancing stand and arbor

2. Automatic infeed attachment

3. Manual feeder for infeed grinding (up and down)

4. Hydraulic work ejector (infeed grinding)

5. Automatic loading attachment (thrufeed grinding) (Ø5-20 mm, L100-600 mm)

6. Automatic feeder for thrufeed grinding (hopper type) (Ø2-8 mm, L50-180 mm)

7. Automatic unloading attachment (thrufeed grinding)

8. V Type Supporter for long bar grinding

9. Profile grinding attachment

10. Magnetic coolant separator

11. Magnetic with paper filter

12. Hydrocyclone coolant separator

13. Auto. Loading and unloading attachment (infeed grinding)

14. Vibratory feeder (thrufeed grinding)

15. Large work rest (thrufeed grinding) L:250 – 500 mm

2. Automatic infeed attachment

3. Manual feeder for infeed grinding (up and down)

4. Hydraulic work ejector (infeed grinding)

5. Automatic loading attachment (thrufeed grinding) (Ø5-20 mm, L100-600 mm)

6. Automatic feeder for thrufeed grinding (hopper type) (Ø2-8 mm, L50-180 mm)

7. Automatic unloading attachment (thrufeed grinding)

8. V Type Supporter for long bar grinding

9. Profile grinding attachment

10. Magnetic coolant separator

11. Magnetic with paper filter

12. Hydrocyclone coolant separator

13. Auto. Loading and unloading attachment (infeed grinding)

14. Vibratory feeder (thrufeed grinding)

15. Large work rest (thrufeed grinding) L:250 – 500 mm

PC-12S/14S/16S

● Regulating wheel is driven by servomotor

● Low speeds; hing torque output.

● Easy to operate and adjust.

● Regulating wheel is driven by servomotor.

● Low speed; high torque output.

● Easy to operate and adjust.

Features:

- Feed Screw

- ‧The feed screw is manufactured from Nickel Chromolybedenum alloy steel (SNCM-4). It is also normalized, high frequency hardened treated and precision ground.

- ‧Specially-designed adjustable nut features easy adjustment, high feeding accuracy, smooth motion and excellent wear resistance.

- Slide Table

- ‧Upper slide swiveling is easy and accurate to adjust for making the machine suitable for infeeding grinding. Also, it allows grinding for a varied diameter of workpieces. The Upper slide with +5°~ -5° swiveling allows taper grinding by using infeed grinding mode.

- ‧With thrufeed grinding, the Upper slide provides a surface contact adjustment between the workpiece and grinding wheel. Swiveling adjustment range is +5°~ -3°.

- ‧Dovetailed slideway on the upper slide features smooth and accurate feeding and is lubricated by a centralized lubricator.

- ‧The bottom slide moves on "Λ" shaped and double-wedged ways. The slideways are hardened and precision ground. They feature smooth movement and properly protected to prevent dust from entering. Micrometric feed adjustment unit is 0.001 mm to meet high accuracy requirements for all workpieces.

- Dresser for Grinding Wheel and Regulating Wheel

- ‧Dresser structure is manufactured from alloy cast iron and is heat treated for wear resistance.

- ‧Hydraulically operated dressing motion.

- ‧Variable dressing speed.

- ‧Dresser stand for regulating wheel can be adjusted to suit workpiece requirements, assuring high cylindrical accuracy.

- Automatic Loading Equipment for Thrufeed Grinding (Optional)

- ‧Suitable for automatic loading operation for round tube and bar stock.

- ‧Equipped with a storage tray for automatic workpiece infeed.

- ‧It eliminates manual workpiece infeed while enormously increasing total efficiency.

- Automatic Unloading Equipment for Thrufeed Grinding (Optional)

- ‧Designed for automatic unloading for round tubes and bar stock. This equipment avoids workpiece surface scratching. It is also suitable for online operation while performing two to three grinding processes. The conveyor is easy to adjust. Equipped with a parts tray for convenient parts collection after grinding.

Specifications:

| SPECIFICATIONS | PC-12S | PC-14S | PC-16S |

| Grinding Wheel | |||

| Standard grinding range (Dia.) | |||

| Capacity increases with special arrangement | |||

| Grinding wheel size (O.D. x width x I.D.) | |||

| Grinding wheel speed | 1900 R.P.M. | 1637 R.P.M. | 1600 R.P.M. |

| Grinding wheel motor | 7-1/2 HP x 4P | 7-1/2 HP x 4P | 10 HP x 4P |

| Regulating Wheel | |||

| Regulating wheel size (O.D. x width x I.D.) | |||

| Regulating wheel speed | 10~300 R.P.M. (Variable) | 10~300 R.P.M. (Variable) | 10~300 R.P.M. (Variable) |

| Regulating wheel motor | 1.5 KW servo motor | 1.5 KW servo motor | 2.0 KW servo motor |

| Regulating wheel tilt angle | +5 | +5 | +5 |

| Regulating wheel swivel angle | |||

| Handwheel Graduation | |||

| Upper slide feed graduation | 4 mm/rev. | 4 mm/rev. | 3.5 mm/rev. |

| Upper slide micro-feed graduation | 0.1 mm/rev. | 0.1 mm/rev. | 0.1 mm/rev. |

| Lower slide feed graduation | 7 mm/rev. | 7 mm/rev. | 9 mm/rev. |

| Lower slide micro-feed graduation | 0.2 mm/rev. | 0.2 mm/rev. | 0.2 mm/rev. |

| Trimming device graduation | 1.25 mm/rev. | 1.25 mm/rev. | 2 mm/rev. |

| Drive Motors | |||

| Hydraulic pump motor | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P |

| Coolant pump motor | 1/8 HP x 2P | 1/8 HP x 2P | 1/4 HP x 2P |

| Machine Dimensions | 1750 x 1050 x 1400 mm | 1750 x 1050 x 1400 mm | 2100 x 1700 x 1500 mm |

| Net weight | 1650 kgs | 1750 kgs | 2400 kgs |

| Gross weight | 1900 kgs | 2000 kgs | 2700 kgs |

| Packing dimensions | 2280 x 1100 x 1740 mm | 2280 x 1100 x 1740 mm | 2280 x 1850 x 1850 mm |

● Low speeds; hing torque output.

● Easy to operate and adjust.

| SPECIFICATIONS | PC-18S | PC-1810S | PC-1812S, | PC-20S |

| Grinding Wheel | ||||

| Standard grinding range (Dia.) | ||||

| Capacity increases with special arrangement | ||||

| Grinding wheel size (O.D. x width x I.D.) | ||||

| Grinding wheel speed | 1500 R.P.M. | 1500 R.P.M. | 1500 R.P.M. | 1200 R.P.M. |

| Grinding wheel motor | 15 HP x 4P | 15 HP x 4P | 20 HP x 4P | 20 HP x 4P |

| Regulating Wheel | ||||

| Regulating Wheel size (O.D. x width x I.D.) | ||||

| Regulating Wheel speed | 10~300 R.P.M. (Variable) | 10~300 R.P.M. (Variable) | 10~300 R.P.M. (Variable) | 10~300 R.P.M. (Variable) |

| Regulating Wheel motor / S series | 3.0 KW servo motor | 3.0 KW servo motor | 3.5 KW servo motor | 3.5 KW servo motor |

| Regulating Wheel tilt angle | +5 | +5 | +5 | +5 |

| Regulating Wheel swivel angle | ||||

| Handwheel Graduation | ||||

| Upper slide feed graduation | 3.5 mm/rev. | 3.5 mm/rev. | 3.5 mm/rev. | 3.5 mm/rev. |

| Upper slide micro-feed graduation | 0.1 mm/rev. | 0.1 mm/rev. | 0.1 mm/rev. | 0.1 mm/rev. |

| Lower slide feed graduation | 9 mm/rev. | 9 mm/rev. | 9 mm/rev. | 9 mm/rev. |

| Trimming device graduation | 2 mm/rev. | 2 mm/rev. | 2 mm/rev. | 2 mm/rev. |

| Drive Motors | ||||

| Hydraulic pump motor | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P |

| Coolant pump motor | 1/4 HP x 2P | 1/4 HP x 2P | 1/4 HP x 2P | 1/4 HP x 2P |

| Machine Dimensions | 2200 x 1840 x 1530 mm | 2200 x 1840 x 1530 mm | 2350 x 1950 x 1530 mm | 2200 x 1900 x 1530 mm |

| Net weight | 3000 kgs | 3000 kgs | 3500 kgs | 3600 kgs |

| Gross weight | 3300 kgs | 3300 kgs | 3800 kgs | 3900 kgs |

| Packing dimensions | 2450 x 1940 x 1900 mm | 2280 x 1940 x 1850 mm | 2690 x 2100 x 1900 mm | 2690 x 2100 x 1900 mm |

● Low speed; high torque output.

● Easy to operate and adjust.

Standard Accessories:

1. Regulating wheel and flange (1 set) (mounted on machine)

2. Grinding wheel and flange (1 set) (mounted on machine)

3. Infeed work rest and carbide blade (1 set)

4. Thrufeed work rest and carbide blade (1 set)

5. Standard electric equipment (1 set) (mounted on machine)

6. Oil tank (1 set) (incl. oil cooling fan)

7. Standard coolant system (1 set)

8. Diamond tools (2 pcs) (mounted on machine)

9. Work lamp (1 set) (mounted on machine)

10. Tool box and kits (1 set)

2. Grinding wheel and flange (1 set) (mounted on machine)

3. Infeed work rest and carbide blade (1 set)

4. Thrufeed work rest and carbide blade (1 set)

5. Standard electric equipment (1 set) (mounted on machine)

6. Oil tank (1 set) (incl. oil cooling fan)

7. Standard coolant system (1 set)

8. Diamond tools (2 pcs) (mounted on machine)

9. Work lamp (1 set) (mounted on machine)

10. Tool box and kits (1 set)

Optional Accessories:

1. Wheel balancing stand and arbor

2. Automatic infeed attachment

3. Manual feeder for ifeed grinding (up and down)

4. Hydraulic work ejector (infeed grinding)

5. Automatic loading attachment (thrufeed grinding) (Ø5-20 mm, L100-600 mm)

6. Automatic feeder for thrufeed grinding (hopper type) (Ø2-8 mm, L50-180 mm)

7. Automatic unloading attachment (thrufeed grinding)

8. V type supporter for long bar grinding

9. Profile grinding attachment

10. Magnetic coolant separator

11. Magnetic with paper filter

12. Hydrocydone coolant separator

13. Auto. Loading and unloading attachment (infeed grinding)

14. Vibratory feeder (thrufeed grinding)

15. Large work rest (thrufeed grinding) L: 250 – 500 mm

2. Automatic infeed attachment

3. Manual feeder for ifeed grinding (up and down)

4. Hydraulic work ejector (infeed grinding)

5. Automatic loading attachment (thrufeed grinding) (Ø5-20 mm, L100-600 mm)

6. Automatic feeder for thrufeed grinding (hopper type) (Ø2-8 mm, L50-180 mm)

7. Automatic unloading attachment (thrufeed grinding)

8. V type supporter for long bar grinding

9. Profile grinding attachment

10. Magnetic coolant separator

11. Magnetic with paper filter

12. Hydrocydone coolant separator

13. Auto. Loading and unloading attachment (infeed grinding)

14. Vibratory feeder (thrufeed grinding)

15. Large work rest (thrufeed grinding) L: 250 – 500 mm

PC-18S/1810S/1812S/20S

Features:

- Feed Screw

- ‧The feed screw is manufactured from Nickel Chromolybedenum alloy steel (SNCM-4). It is also normalized, high frequency hardened treated and precision ground.

- ‧Specially-designed adjustable nut features easy adjustment, high feeding accuracy, smooth motion and excellent wear resistance.

- Slide Table

- ‧Upper slide swiveling is easy and accurate to adjust for making the machine suitable for infeeding grinding. Also, it allows grinding for a varied diameter of workpieces. The Upper slide with +5°~ -5° swiveling allows taper grinding by using infeed grinding mode.

- ‧With thrufeed grinding, the Upper slide provides a surface contact adjustment between the workpiece and grinding wheel. Swiveling adjustment range is +5°~ -3°.

- ‧Dovetailed slideway on the upper slide features smooth and accurate feeding and is lubricated by a centralized lubricator.

- ‧The bottom slide moves on "Λ" shaped and double-wedged ways. The slideways are hardened and precision ground. They feature smooth movement and properly protected to prevent dust from entering. Micrometric feed adjustment unit is 0.001 mm to meet high accuracy requirements for all workpieces.

- Dresser for Grinding Wheel and Regulating Wheel

- ‧Dresser structure is manufactured from alloy cast iron and is heat treated for wear resistance.

- ‧Hydraulically operated dressing motion.

- ‧Variable dressing speed.

- ‧Dresser stand for regulating wheel can be adjusted to suit workpiece requirements, assuring high cylindrical accuracy.

- Automatic Loading Equipment for Thrufeed Grinding (Optional)

- ‧Suitable for automatic loading operation for round tube and bar stock.

- ‧Equipped with a storage tray for automatic workpiece infeed.

- ‧It eliminates manual workpiece infeed while enormously increasing total efficiency.

- Automatic Unloading Equipment for Thrufeed Grinding (Optional)

- ‧Designed for automatic unloading for round tubes and bar stock. This equipment avoids workpiece surface scratching. It is also suitable for online operation while performing two to three grinding processes. The conveyor is easy to adjust. Equipped with a parts tray for convenient parts collection after grinding.

Specifications:

| SPECIFICATIONS | PC-12S | PC-14S | PC-16S |

| Grinding Wheel | |||

| Standard grinding range (Dia.) | |||

| Capacity increases with special arrangement | |||

| Grinding wheel size (O.D. x width x I.D.) | |||

| Grinding wheel speed | 1900 R.P.M. | 1637 R.P.M. | 1600 R.P.M. |

| Grinding wheel motor | 7-1/2 HP x 4P | 7-1/2 HP x 4P | 10 HP x 4P |

| Regulating Wheel | |||

| Regulating wheel size (O.D. x width x I.D.) | |||

| Regulating wheel speed | 10~300 R.P.M. (Variable) | 10~300 R.P.M. (Variable) | 10~300 R.P.M. (Variable) |

| Regulating wheel motor | 1.5 KW servo motor | 1.5 KW servo motor | 2.0 KW servo motor |

| Regulating wheel tilt angle | +5 | +5 | +5 |

| Regulating wheel swivel angle | |||

| Handwheel Graduation | |||

| Upper slide feed graduation | 4 mm/rev. | 4 mm/rev. | 3.5 mm/rev. |

| Upper slide micro-feed graduation | 0.1 mm/rev. | 0.1 mm/rev. | 0.1 mm/rev. |

| Lower slide feed graduation | 7 mm/rev. | 7 mm/rev. | 9 mm/rev. |

| Lower slide micro-feed graduation | 0.2 mm/rev. | 0.2 mm/rev. | 0.2 mm/rev. |

| Trimming device graduation | 1.25 mm/rev. | 1.25 mm/rev. | 2 mm/rev. |

| Drive Motors | |||

| Hydraulic pump motor | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P |

| Coolant pump motor | 1/8 HP x 2P | 1/8 HP x 2P | 1/4 HP x 2P |

| Machine Dimensions | 1750 x 1050 x 1400 mm | 1750 x 1050 x 1400 mm | 2100 x 1700 x 1500 mm |

| Net weight | 1650 kgs | 1750 kgs | 2400 kgs |

| Gross weight | 1900 kgs | 2000 kgs | 2700 kgs |

| Packing dimensions | 2280 x 1100 x 1740 mm | 2280 x 1100 x 1740 mm | 2280 x 1850 x 1850 mm |

● Low speeds; hing torque output.

● Easy to operate and adjust.

| SPECIFICATIONS | PC-18S | PC-1810S | PC-1812S | PC-20S |

| Grinding Wheel | ||||

| Standard grinding range (Dia.) | ||||

| Capacity increases with special arrangement | ||||

| Grinding wheel size (O.D. x width x I.D.) | ||||

| Grinding wheel speed | 1500 R.P.M. | 1500 R.P.M. | 1500 R.P.M. | 1200 R.P.M. |

| Grinding wheel motor | 15 HP x 4P | 15 HP x 4P | 20 HP x 4P | 20 HP x 4P |

| Regulating Wheel | ||||

| Regulating Wheel size (O.D. x width x I.D.) | ||||

| Regulating Wheel speed | 10~300 R.P.M. (Variable) | 10~300 R.P.M. (Variable) | 10~300 R.P.M. (Variable) | 10~300 R.P.M. (Variable) |

| Regulating Wheel motor / S series | 3.0 KW servo motor | 3.0 KW servo motor | 3.5 KW servo motor | 3.5 KW servo motor |

| Regulating Wheel tilt angle | +5 | +5 | +5 | +5 |

| Regulating Wheel swivel angle | ||||

| Handwheel Graduation | ||||

| Upper slide feed graduation | 3.5 mm/rev. | 3.5 mm/rev. | 3.5 mm/rev. | 3.5 mm/rev. |

| Upper slide micro-feed graduation | 0.1 mm/rev. | 0.1 mm/rev. | 0.1 mm/rev. | 0.1 mm/rev. |

| Lower slide feed graduation | 9 mm/rev. | 9 mm/rev. | 9 mm/rev. | 9 mm/rev. |

| Trimming device graduation | 2 mm/rev. | 2 mm/rev. | 2 mm/rev. | 2 mm/rev. |

| Drive Motors | ||||

| Hydraulic pump motor | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P | 1 HP x 4P |

| Coolant pump motor | 1/4 HP x 2P | 1/4 HP x 2P | 1/4 HP x 2P | 1/4 HP x 2P |

| Machine Dimensions | 2200 x 1840 x 1530 mm | 2200 x 1840 x 1530 mm | 2350 x 1950 x 1530 mm | 2200 x 1900 x 1530 mm |

| Net weight | 3000 kgs | 3000 kgs | 3500 kgs | 3600 kgs |

| Gross weight | 3300 kgs | 3300 kgs | 3800 kgs | 3900 kgs |

| Packing dimensions | 2450 x 1940 x 1900 mm | 2280 x 1940 x 1850 mm | 2690 x 2100 x 1900 mm | 2690 x 2100 x 1900 mm |

● Low speed; high torque output.

● Easy to operate and adjust.

Standard Accessories:

1. Regulating wheel and flange (1 set) (mounted on machine)

2. Grinding wheel and flange (1 set) (mounted on machine)

3. Infeed work rest and carbide blade (1 set)

4. Thrufeed work rest and carbide blade (1 set)

5. Standard electric equipment (1 set) (mounted on machine)

6. Oil tank (1 set) (incl. oil cooling fan)

7. Standard coolant system (1 set)

8. Diamond tools (2 pcs) (mounted on machine)

9. Work lamp (1 set) (mounted on machine)

10. Tool box and kits (1 set)

2. Grinding wheel and flange (1 set) (mounted on machine)

3. Infeed work rest and carbide blade (1 set)

4. Thrufeed work rest and carbide blade (1 set)

5. Standard electric equipment (1 set) (mounted on machine)

6. Oil tank (1 set) (incl. oil cooling fan)

7. Standard coolant system (1 set)

8. Diamond tools (2 pcs) (mounted on machine)

9. Work lamp (1 set) (mounted on machine)

10. Tool box and kits (1 set)

Optional Accessories:

1. Wheel balancing stand and arbor

2. Automatic infeed attachment

3. Manual feeder for ifeed grinding (up and down)

4. Hydraulic work ejector (infeed grinding)

5. Automatic loading attachment (thrufeed grinding) (Ø5-20 mm, L100-600 mm)

6. Automatic feeder for thrufeed grinding (hopper type) (Ø2-8 mm, L50-180 mm)

7. Automatic unloading attachment (thrufeed grinding)

8. V type supporter for long bar grinding

9. Profile grinding attachment

10. Magnetic coolant separator

11. Magnetic with paper filter

12. Hydrocydone coolant separator

13. Auto. Loading and unloading attachment (infeed grinding)

14. Vibratory feeder (thrufeed grinding)

15. Large work rest (thrufeed grinding) L: 250 – 500 mm

2. Automatic infeed attachment

3. Manual feeder for ifeed grinding (up and down)

4. Hydraulic work ejector (infeed grinding)

5. Automatic loading attachment (thrufeed grinding) (Ø5-20 mm, L100-600 mm)

6. Automatic feeder for thrufeed grinding (hopper type) (Ø2-8 mm, L50-180 mm)

7. Automatic unloading attachment (thrufeed grinding)

8. V type supporter for long bar grinding

9. Profile grinding attachment

10. Magnetic coolant separator

11. Magnetic with paper filter

12. Hydrocydone coolant separator

13. Auto. Loading and unloading attachment (infeed grinding)

14. Vibratory feeder (thrufeed grinding)

15. Large work rest (thrufeed grinding) L: 250 – 500 mm