Detailed:

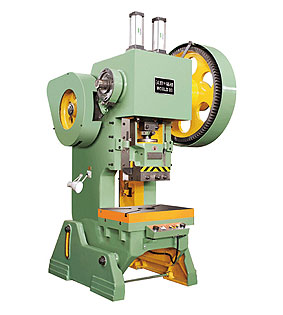

The machine features fine steel plates welded machine body, tempering treatment (or vibration relief), shot blasting, rigidness, accuracy and stability.

Vertical located crank shaft, compact structure; the crank shaft undergoes grinding treatment after high frequency quenching, which has a good smooth finish and rotates flexibly; lengthened rectangle hex guideway with a surface of bronze plate, which has high guide accuracy.

Pneumatic dual balance cylinder, balanced sliding block and punch weight, which reduce impact and noise, eliminate the clearance between connecting rod and sliding block, reduce the impact and wear of the stress parts. The whole machine adopt PLC centralized control, the gas circuits adopt imported safety dual valve, which can achieve jog, inch, single and continuous punching; the key parts such as sliding block, guideways, worktable plate, connecting rod, and are all castings made of resin sand, which improved the surface roughness 1-2 level, and improve the size accuracy 2-3 level.

The 60T-level machines adopt the electrical control device to adjust the die height. Fine configuration, the key parts like pneumatic components, electrical components, sealing parts, buttons and etc all adopt imported parts. There are optional dry or wet friction clutch, and optional hydraulic overload protection device or press-down type safety device, all of them can be equipped with automatic lubrication, photoelectric protection, frequency conversion and speed control, air blowing device and etc according to customer needs.

| Parameters |

R |

Unit |

JH21-25 |

JH21-45 |

JH21-60 |

JH21-80 |

JH21-125 |

JH21-160 |

JH21-200 |

JH21-250 |

JH21-315 |

| Nominal pressure on sliding block |

Pe |

KN |

250 |

450 |

600 |

800 |

1250 |

1600 |

2000 |

2500 |

3150 |

| Nominal pressure stroke Sp |

Sp |

mm |

3 |

4 |

4 |

5 |

6 |

6 |

6 |

6 |

7 |

| Slide stroke |

S |

mm |

80 |

120 |

140 |

160 |

180 |

200 |

250 |

250 |

250 |

| Stroke frequency |

Fixed |

n |

times

/min |

100 |

80 |

70 |

60 |

50 |

45 |

45 |

30 |

30 |

| Variable |

60-100 |

50-80 |

45-70 |

40-60 |

35-50 |

30-45 |

25-45 |

20-30 |

20-30 |

| Die height |

H2 |

mm |

250 |

270 |

300 |

320 |

350 |

400 |

450 |

500 |

500 |

| Die Height Adjustment |

t |

mm |

50 |

60 |

70 |

80 |

90 |

100 |

110 |

120 |

120 |

| Distance between slider center and machine |

C1 |

mm |

210 |

225 |

270 |

310 |

350 |

390 |

430 |

450 |

450 |

| Vertical columns distance |

d1 |

mm |

450 |

500 |

560 |

620 |

680 |

720 |

900 |

980 |

980 |

| Slider bottom size |

L��R |

a |

mm |

360 |

410 |

480 |

540 |

620 |

700 |

880 |

950 |

950 |

| F��B |

b |

mm |

250 |

340 |

400 |

460 |

520 |

580 |

650 |

700 |

700 |

| Size of handle hole |

Diameter |

d |

mm |

40 |

50 |

50 |

50 |

70 |

70 |

70 |

70 |

70 |

| Depth |

I |

mm |

65 |

60 |

70 |

65 |

90 |

100 |

100 |

130 |

130 |

| Size of worktable |

L��R |

C |

mm |

720 |

810 |

920 |

950 |

1070 |

1170 |

1390 |

1500 |

1540 |

| F��B |

D |

mm |

400 |

440 |

520 |

600 |

680 |

760 |

840 |

880 |

880 |

| Thickness of worktable |

H3 |

mm |

80 |

110 |

130 |

140 |

155 |

165 |

180 |

190 |

190 |

| Worktable height |

H1 |

mm |

780 |

800 |

900 |

900 |

900 |

900 |

920 |

920 |

1000 |

| Size |

F��B |

A |

mm |

1346 |

1435 |

1540 |

1765 |

2040 |

2305 |

2690 |

2660 |

2720 |

| L��R |

B |

mm |

945 |

1075 |

1200 |

1200 |

1320 |

1420 |

1540 |

1640 |

1680 |

| H |

H |

mm |

2120 |

2391 |

2570 |

2725 |

3035 |

3215 |

3810 |

3785 |

3865 |

| Anchor bolts distance |

F��B |

a1 |

mm |

830 |

950 |

1100 |

1210 |

1510 |

1670 |

2020 |

2150 |

2140 |

| L��R |

b1 |

mm |

690 |

745 |

840 |

920 |

1040 |

1140 |

1360 |

1460 |

1500 |

| Power of electric motor |

Model |

Y100L2-4 |

Yl32S-4 |

Yl32S-4 |

Yl32M-4 |

Yl60M-4 |

Yl60L-4 |

Yl80M-4 |

Y200L2-6 |

Y225M-6 |

| Power |

KW |

3 |

5.5 |

5.5 |

7.5 |

11 |

15 |

18.5 |

22 |

30 |

| Weight (Approximate) |

|

KG |

2380 |

3500 |

5150 |

7950 |

10350 |

15400 |

20500 |

23600 |

27600 | |